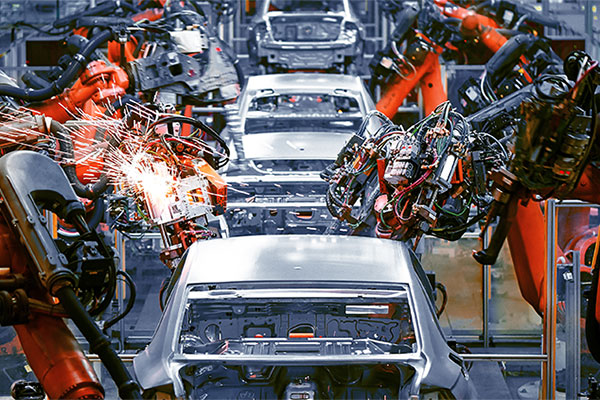

As technology continues to advance, the auto manufacturing industry has seen significant changes in the materials used to build vehicles. Advanced materials have revolutionized the way cars are constructed, providing a wide range of benefits including increased safety, improved fuel efficiency, and enhanced performance.

Aluminum

One of the most commonly used advanced materials in modern auto manufacturing is aluminum. This lightweight metal is highly durable and corrosion-resistant, making it an ideal choice for car manufacturers looking to reduce weight and improve fuel efficiency. In fact, the use of aluminum in car manufacturing can reduce a vehicle’s weight by up to 40%, which can result in significant fuel savings and reduced emissions.

Carbon Fiber

Carbon fiber is another advanced material that has become increasingly popular in the auto manufacturing industry. This lightweight material is stronger than steel and aluminum, yet weighs significantly less, making it an ideal choice for high-performance vehicles. Carbon fiber is often used in the construction of sports cars and racing cars, where weight reduction is critical for achieving maximum speed and performance.

Titanium

Titanium is a lightweight and incredibly strong metal that is commonly used in aerospace and military applications. In recent years, car manufacturers have begun to incorporate this advanced material into their designs, particularly in high-performance vehicles. The use of titanium in auto manufacturing can significantly reduce weight while maintaining strength and durability, resulting in improved performance and fuel efficiency.

Advanced Plastics

Advanced plastics are also playing a greater role in modern auto manufacturing. These materials are lightweight, strong, and offer excellent resistance to impact and corrosion. They are often used in the construction of vehicle body panels, reducing weight and improving fuel efficiency. Advanced plastics are also becoming increasingly popular in the production of electric and hybrid vehicles, where weight reduction is critical for achieving maximum range and efficiency.

Conclusion

The use of advanced materials in modern auto manufacturing has transformed the industry, providing car manufacturers with a wide range of benefits including improved safety, enhanced performance, and increased fuel efficiency. From aluminum and carbon fiber to titanium and advanced plastics, these materials are helping to create lighter, stronger, and more efficient vehicles that are better for the environment and more enjoyable to drive.