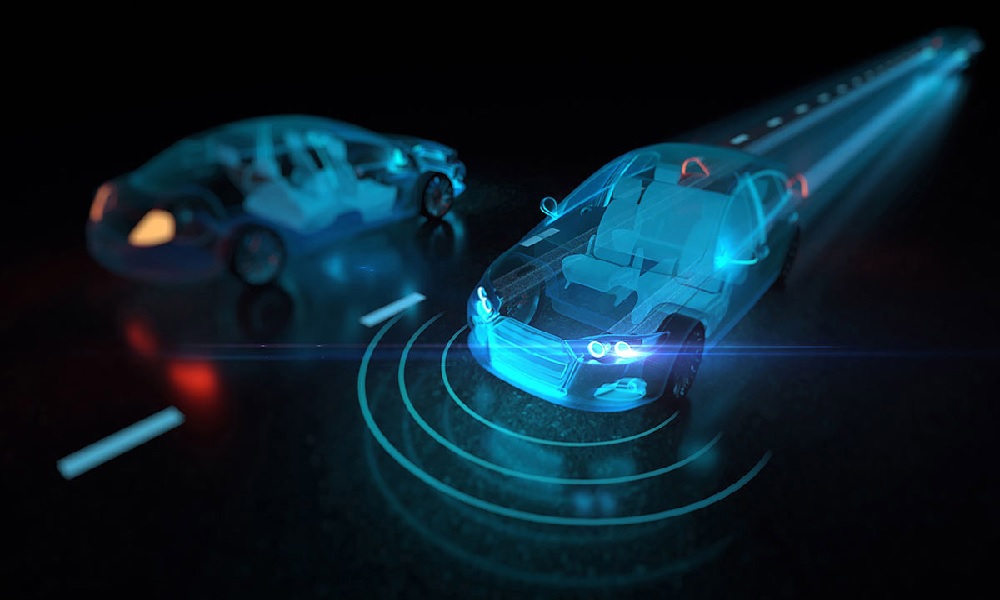

In recent years, the auto industry has been undergoing a major transformation. With the rapid development of technology, cars are no longer just a means of transportation but are becoming more intelligent and connected. One of the latest technologies that have been emerging in the auto industry is the digital twin technology.

What is Digital Twin Technology?

Digital twin technology is a virtual replica of a physical product, process, or system. It uses real-time data and simulation to create a digital representation of a physical object or system, which helps to predict its behavior and performance. In the auto industry, digital twin technology is used to create a virtual replica of a car, which can be used to simulate and test various scenarios before the actual car is produced.

How is Digital Twin Technology Used in the Auto Industry?

Digital twin technology is being used in various ways in the auto industry. One of the primary uses of this technology is in the design and development of cars. By creating a virtual replica of a car, designers can test different designs and configurations before the actual car is produced. This helps to reduce the time and cost of the design process and ensures that the final product meets the desired specifications.

Another use of digital twin technology in the auto industry is in the manufacturing process. By creating a virtual representation of the manufacturing process, manufacturers can identify potential issues and optimize the process before the actual production begins. This helps to reduce the risk of errors and improves the efficiency of the manufacturing process.

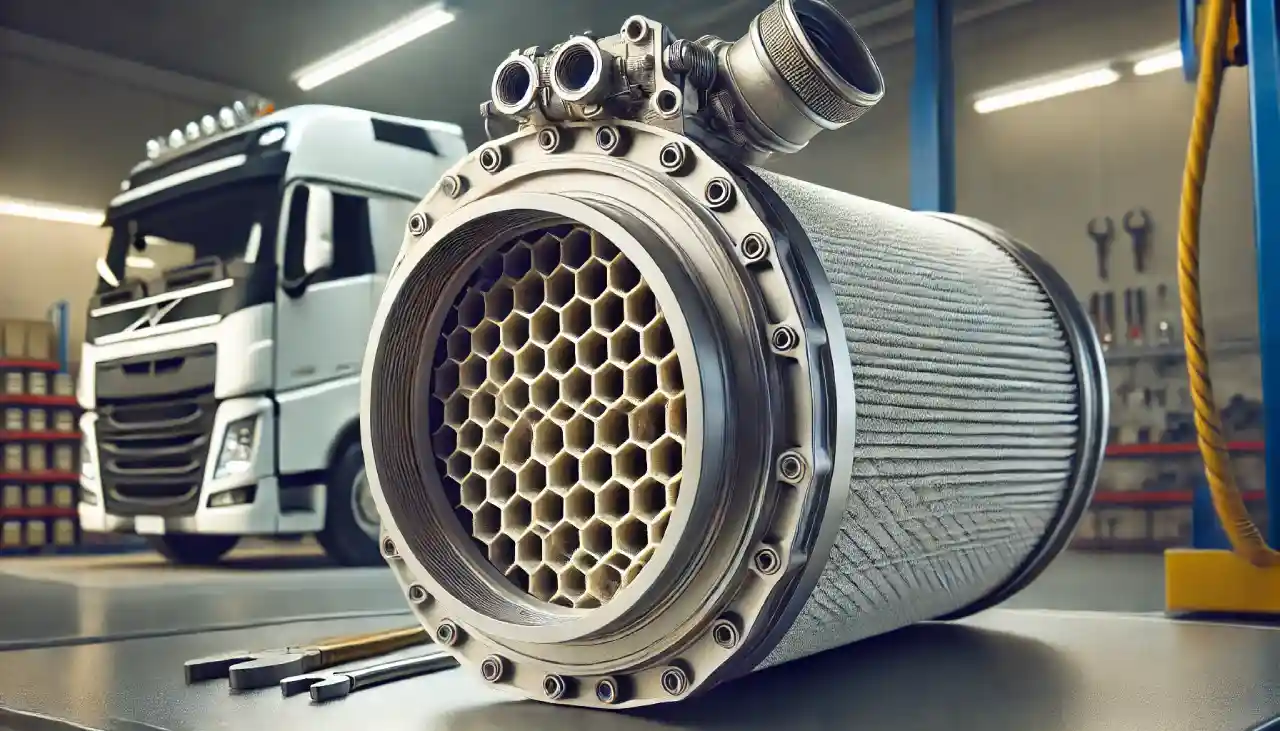

Additionally, digital twin technology is being used in the maintenance and repair of cars. By creating a virtual replica of a car, mechanics can diagnose and troubleshoot problems without having to physically inspect the car. This helps to reduce the time and cost of maintenance and repair and ensures that the car is back on the road as quickly as possible.

Benefits of Digital Twin Technology in the Auto Industry

There are several benefits of using digital twin technology in the auto industry. One of the primary benefits is that it helps to reduce the time and cost of the design and development process. By simulating and testing various scenarios before the actual production, designers can identify potential issues and make necessary changes before the car is produced. This helps to ensure that the final product meets the desired specifications and is of high quality.

Another benefit of digital twin technology is that it helps to improve the efficiency of the manufacturing process. By identifying potential issues and optimizing the process before the actual production, manufacturers can reduce the risk of errors and improve the efficiency of the manufacturing process. This helps to reduce the time and cost of production and ensures that the final product is of high quality.

Furthermore, digital twin technology helps to improve the maintenance and repair process of cars. By creating a virtual replica of a car, mechanics can diagnose and troubleshoot problems without having to physically inspect the car. This helps to reduce the time and cost of maintenance and repair and ensures that the car is back on the road as quickly as possible.

Conclusion

Digital twin technology is a game-changing technology that is transforming the auto industry. By creating a virtual replica of a car, designers, manufacturers, and mechanics can simulate, test, and diagnose various scenarios before the actual production. This helps to reduce the time and cost of the design, development, manufacturing, maintenance, and repair processes and ensures that the final product is of high quality. As technology continues to evolve, it is likely that digital twin technology will become even more prevalent in the auto industry.